Traditional purge systems present significant limitations as they are inefficient, costly, and labor-intensive. Additionally, conventional purge systems must be placed far from the weld zone (10-20 ft.) adding unnecessary inconvenience and costs to the welding process.

To overcome these limitations, Aquasol Water Soluble Paper and Tape were introduced. Together these components can be constructed by hand into unique purge dams. They are able to be placed within close proximity of the weld zone, thereby increasing efficiency of the entire welding process.

Aquasol Water Soluble Paper provides an excellent barrier used to retain noble gases such as argon and helium within the weld zone during TIG welding of stainless steel and aluminum pipes.

Comprised of sodium carboxyl methyl cellulose and wooden pulp, Aquasol Water Soluble Paper dissolves quickly and completely in most liquids, including water. Its 100% bio-degradable composition leaves no residue behind in the pipeline.

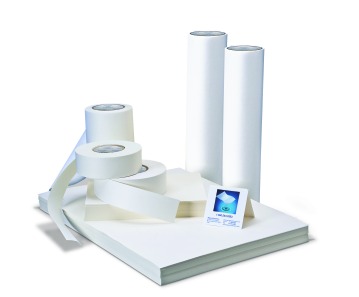

Aquasol Water Soluble Paper is available in a wide range of grades and sizes permitting the construction of purge dams for any pipe diameter. Extremely easy to store, non-toxic and environmentally friendly, Aquasol Water Soluble Paper is ideal for the nuclear, petrochemical, and food and beverage industries.

Aquasol Water Soluble Paper provides an excellent barrier used to retain noble gases such as argon and helium within the weld zone during TIG welding of stainless steel and aluminum pipes.

Low Air Permeable Purge Gas Barrier for Any Pipe Diameter

• Made of sodium carboxy methyl cellulose & wooden pulp

• Creates excellent barrier for retaining noble gas

• Simple and fast construction that can be customized to fit various pipe schedules and sizes

• Saves money on gas consumption as paper can be placed in close proximity to the weld zone, thereby using less inert gas to displace oxygen in the purge chamber

• EPA and CE approved

• Easily secures to inner pipe wall with use of Aquasol Water Soluble Tape, creating an air-tight seal

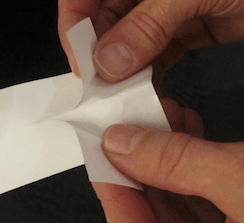

Trace pipe’s inner diameter by pressing paper along pipe edge, creating an impression. Then fold to form a 90° angle.

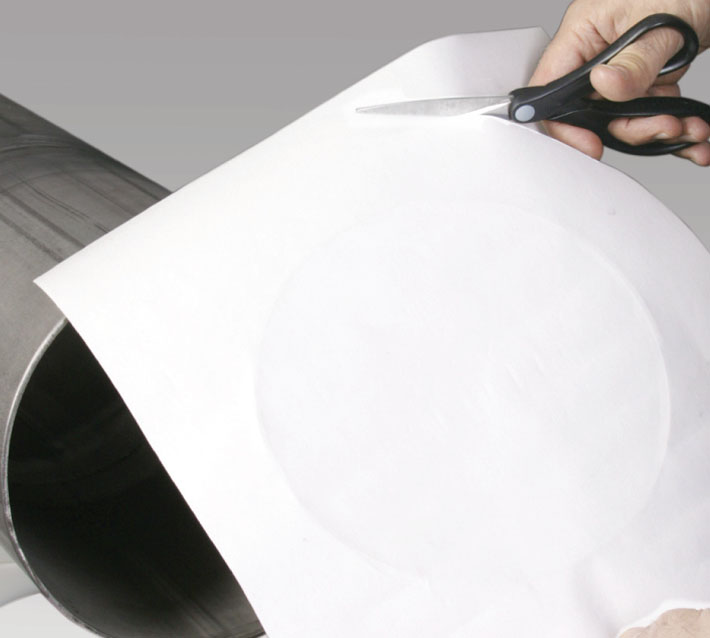

Cut in a circle around the impression, approximately one-third times greater than pipe diameter.

Slit approximately 1″ to 2″ segments perpendicular to impression on paper making first slit at 12 o’clock position followed by 3 o’clock, 6 o’clock and so on.

Cut Aquasol Water Soluble Tape into pieces. Position slit Aquasol Water Soluble Paper dam inside pipe. Secure dam with tape pieces along the entire circumference.

Moisten an ordinary sponge with water and squeeze out excess water until sponge is damp.

Lightly dab sponge along the water soluble tape portion of the dam. The dampened sponge will reactivate the adhesive to ensure low air permeability.

Repeat process on the opposite side of the pipe to close the purge chamber parameters.

Insert purge gas needle into root gap and introduce noble gas, while ensuring connection to gas line.

Carry out the welding process.

Dissolve Aquasol Water Soluble Paper and Tape by introducing water when performing hydro-test.

| Pipe Diameter | Recommended Distance | ||

|---|---|---|---|

| English | Metric | English | Metric |

| 2″ – 8″ | 51 – 203 mm | 6″ | 152 mm |

| 10″ – 22″ | 254 – 559 mm | 8″ | 203 mm |

| 24″ – 36″ | 610 – 914 mm | 12″ | 305 mm |

| Item No | Thickness | Dimensions | Type | Case Pack | ||

|---|---|---|---|---|---|---|

| English | Metric | English | Metric | |||

| ASW-35/S-112RW | 0.0035″ | 0.088 mm | 8 1/2″ x 11″ | 22 cm x 28 cm | Sheet | 1000 sheets/ream |

| ASW-35/S-14R | 0.0035″ | 0.088 mm | 8 1/2″ x 14″ | 216 mm x 355 mm | Sheet | 500 sheets/ream |

| ASW-35/S-22R | 0.0035″ | 0.088 mm | 17″ x 22″ | 431 mm x 559 mm | Sheet | 500 sheets/ream |

| ASW-60/S-22R | 0.0070″ | 0.177 mm | 15 1/2″ x 22″ | 394 mm x 559 mm | Sheet | 250 sheets/ream |

| ASW-35/R-9 | 0.0035″ | 0.088 mm | 9″ x 165″ | 23 cm x 50 m | Roll | 4 rolls/case |

| ASW-35/R-15 | 0.0035″ | 0.088 mm | 15 1/2″ x 165″ | 39 cm x 50 m | Roll | 4 rolls/case |

| ASW-40C/R20.5 | 0.0040″ | 0.102 mm | 20 1/2″ x 165″ | 52 cm x 50 m | Roll | 4 rolls/case |

| ASW-60/R-15 | 0.0070″ | 0.177 mm | 15 1/2″ x 165″ | 39 cm x 50 m | Roll | 4 rolls/case |

| ASW-60/R-31 | 0.0070″ | 0.177 mm | 31″ x 165″ | 79 cm x 50 m | Roll | 4 rolls/case |

| ASWT-1 | N/A | N/A | 1″ x 300″ | 2.5 cm x 92 m | Roll | 24 rolls/case |

| ASWT-2* | N/A | N/A | 2″ x 300″ | 5 cm x 92 m | Roll | 24 rolls/case |

*Available with EZ Peel Release Liner

| ASW-35 | Use for pipes having 4" inner diameter or less |

| ASW-40C | Use for greater gas retention |

| ASW-60 | Use for pipes having 4" inner diameter or greater |

| ASWT | Use to secure Aquasol Water Soluble Dam in place |

Aquasol Water Soluble Paper and Tape dissolves in most aqueous solutions or steam.

Water Soluble Paper combined with a maximum 20% solution of Ethylene Glycol or Propylene Glycol solution will dissolve. In other words, a solution of at least 80% water is required for the paper to be soluble. As a company, we must advise the client to conduct their own tests as Aquasol’s internal tests are for recommendation purposes only. The company does not take any responsibility or fault with product specified in the field utilizing any chemicals besides water for solubility.

Aquasol Water Soluble Paper and Tape will not dissolve in oil or fuel. The products must be flushed with water, steam or an aqueous solution.

Aquasol Water Soluble Paper and Tape cannot dissolve in solvents such as MEK or acetone. The products must be flushed water, steam or an aqueous solution.

Aquasol Water Soluble Paper and Tape will dissolve in either hot or cold water. However, the rate of dissolvability increases as the temperature of the water increases.

Aquasol Water Soluble Paper and Tape has a flash point equivalent to ordinary paper, which is 450°F (232°C).

Aquasol Water Soluble Paper and Tape are CE and EPA approved. It is 100% biodegradable and environmentally friendly. They are safe, non-toxic, and will not cause reactions or adverse effects when used.

Aquasol Water Soluble Tape is engineered in such a way that will allow the user to place the dam in the proper position before maximizing the adhesion of the seal. The strength of the “tack” or “stickiness” of the adhesive allows the user to have control and re-position the dam if not properly placed on the first attempt. Once the dam is positioned, the user can increase adhesion by reactivating the adhesive on the tape portion of the dam with a damp sponge. A tight seal will be formed as it dries, creating a zero air permeable environment.

© 2024 Aquasol Corporation. All Right Reserved.