Fiback Fiberglass Weld Backing Tape is an innovative substitute for traditional back purging methods that provides protection to the backside of the weld environment and ensures a high quality finish. Fiback is flexible, heat resistant, and halogen and fluorocarbon-free, enabling it to be a complete solution for plate, sheet and pipe welding needs.

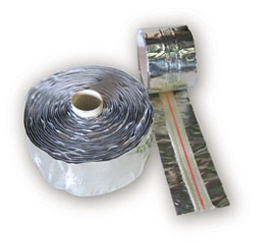

This welding tape is composed of two adhesive areas around the outside edges with a center fiberglass strip, heat resistant up to 1,022°F (550°C) and withstanding applications up to 600 amps.

Suitable for SMAW (stick), TIG, and MIG Welding processes, Fiback can conform to various shapes making it superior to more rigid solutions that develop stress points between pieces and are prone to cracking and breaking over time.

Fiback reduces set-up, clean up and weld time; eliminates post-weld grinding and back gouging and increases work efficiency while minimizing costs.

Fiback 200 AMP

Fiback 600 AMP

Fiback Fiberglass Weld Backing Tape is an innovative substitute for traditional back purging methods that provides protection to the backside of the weld environment and ensures a high-quality finish. Fiback is flexible, heat resistant, and halogen and fluorocarbon-free, enabling it to be a complete solution for plate, sheet and pipe welding needs.

This welding tape is composed of two adhesive areas around the outside edges with a center fiberglass strip, heat resistant up to 1,022°F (550°C) and withstanding applications up to 600 amps.

Flexible

High Quality & Safe Components

Compatibility & Process Applications

Increases Efficiency and Savings

Align

Align desired base metals with the required root gap. Center the fiberglass strip over the backside of the root gap.

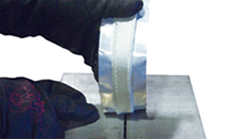

Position

Position the fiberglass strip in a convex shape away from the backside of the weld area to contain the purge gas from the torch tip but avoid consuming the material.

Press

Press the adhesive sections of tape along the sides of the root gap to the base metal, continuing to center the fiberglass strip. Remember to peel the release liner from the aluminum tape while progressing along the weld joint. This procedure ensures the adhesive on the aluminum tape is free from debris and foreign matter.

After Fiback has been applied to the entire length of the metals being joined, press outer adhesive edges again to create an air tight seal between the tape and the base metal.

Weld

Begin welding the desired seam.

| Item No | Description | Width | Fiberglass Center Strip Width | Length |

|---|---|---|---|---|

| AFBT-2.5-200 | Fiback Weld Backing Tape 200 AMP | 2.5″ (64 mm) | 1.125″ (28.5 mm) | 82′ (25 m) |

| AFBT-4.0-200 | Fiback Weld Backing Tape 200 AMP | 4.0″ (102 mm) | 1.5″ (38 mm) | 82′ (25 m) |

| AFBT-2.5 | Fiback Weld Backing Tape 600 AMP | 2.5″ (64 mm) | 1.125″ (28.5 mm) | 41′ (12.5 m) |

| AFBT-4.0 | Fiback Weld Backing Tape 600 AMP | 4.0″ (102 mm) | 1.5″ (38 mm) | 41′ (12.5 m) |

| Adhesive | 500°F | 260°C |

|---|---|---|

| Aluminum Foil | 1100°F | 593°C |

| Fiberglass Strip | 1022°F | 550°C |

The Fiback adhesive has a heat resistance of 500°F (260°C). The fiberglass strip has up to 1,022° F (550°C) heat resistance.

Fiback 600 AMP is durable and flexible enough to easily support the robotic welding.

The Fiback adhesive is halogen and chlorofluorocarbon free. Additionally, it does not contain mercury, antimony, fluorides, bromides, phosphorus, sulfur or lead.

For optimum performance, store Fiback at a temperature of less than 77°F (25°C) and relative humidity of less than 65%.

Fiback has been approved by many reputable companies. For a reference list, please contact customer service.

Fiback is removed by simply peeling away the tape from the weld area. Traditional methods, such as steel backing bars, are removed through air carbon gouging. This process is costly, time consuming, and a danger to the working environment. Using Fiback means bypassing these methods and ensuring safety and efficiency in the workplace.

Compared to other ceramic backing tapes, Fiback is the most flexible solution available. Whereas ceramic backing tape is ridged and unable to conform to irregular surfaces, Fiback can be utilized on essentially any type of shaped piece.

The ridged composition of ceramic backing tape can create stress points which consequently results in cracking or breaking over time. Fiback’s smooth, adaptive composition ensures a clean, continuous weld bead that is not subjected to such vulnerabilities.

© 2024 Aquasol Corporation. All Right Reserved.