Patentes en trámite en EE.UU. y el exterior

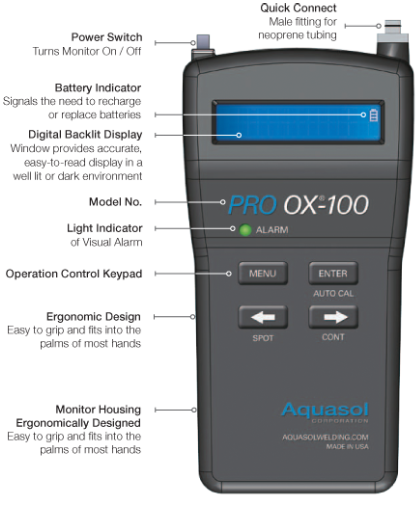

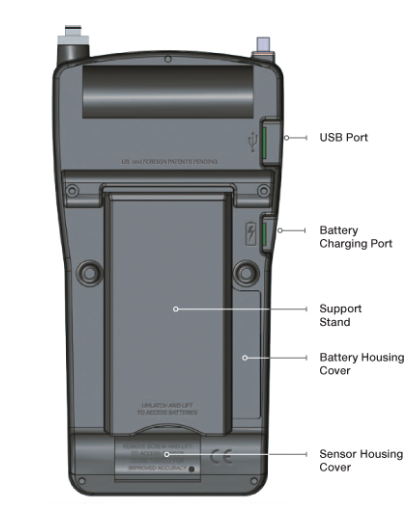

El monitor de oxígeno digital portátil programable Pro OX-100 de Aquasol está diseñado para dar a los operadores las lecturas de niveles de oxígeno más precisas posible.

Internacionalmente reconocido por sus prestaciones de avanzada y bajo costo, este monitor de soldadura autógena autocalibrante con una bomba interna mide con exactitud una resolución de hasta 0,01% (100 ppm) y es ideal para aplicaciones de purgado y otras aplicaciones de soldadura.

Es un gran orgullo fabricar el Pro OX-100, aprobado por la CE, en la Fábrica Certificada por ISO de Aquasol en los EE.UU.

El Pro OX-100 viene equipado con muchas prestaciones de avanzada como sus recursos de registro de datos que permiten a los operadores crear registros permanentes de datos en tiempo real (a intervalos de 15 segundos) y exportar hasta 50 puntos de datos a formato Microsoft® Excel y formato simple de texto.

El Pro OX-100 también ofrece una función multilingüe programable e incorporada con instrucciones en pantalla que están disponibles en inglés, español, alemán y portugués.Con diferentes especificaciones y compatibilidades de voltaje y frecuencia, el Pro OX-100 es el monitor de soldaduras autógenas más universal que existe en el mercado global hoy..

El monitor de oxígeno digital portátil programable Pro OX-100 de Aquasol está diseñado para dar a los operadores las lecturas de niveles de oxígeno más precisas posible.

Internacionalmente reconocido por sus prestaciones de avanzada y bajo costo, este monitor de soldadura autógena autocalibrante con una bomba interna mide con exactitud una resolución de hasta 0,01% (100 ppm) y es ideal para aplicaciones de purgado y otras aplicaciones de soldadura.

Es un gran orgullo fabricar el Pro OX-100, aprobado por la CE, en la Fábrica Certificada por ISO de Aquasol en los EE.UU.

El Pro OX-100 viene equipado con muchas prestaciones de avanzada como sus recursos de registro de datos que permiten a los operadores crear registros permanentes de datos en tiempo real (a intervalos de 15 segundos) y exportar hasta 50 puntos de datos a formato Microsoft® Excel y formato simple de texto.

El Pro OX-100 también ofrece una función multilingüe programable e incorporada con instrucciones en pantalla que están disponibles en inglés, español, alemán y portugués.Con diferentes especificaciones y compatibilidades de voltaje y frecuencia, el Pro OX-100 es el monitor de soldaduras autógenas más universal que existe en el mercado global hoy..

Download Driver Software by completing this form.

Registros de Archivo con Información en Software

Software de Conversión Fácil de Usar

Descarga de Datos Rápida y Cómoda

PUNTUAL:

CONTINUO:

Autocalibrante y Certificado

Alarma Audiovisual

Batería de 9V Recargable y Cargador Diseñados para Voltaje Universal

Denominación CE

Idiomas

Programable en cuatro idiomas populares para satisfacer las necesidades de clientes internacionales

Para Instalar la Tubería de Extensión de Neoprene:

Para Fijar Idioma:

Para Fijar Fecha y Hora:

Para Fijar la Alarma en ENCENDIDO/APAGADO:

Para ver el Registro:

Para Borrar el Registro:

Cómo Calibrar el PRO OX-100:

Modo de Lectura Puntual:

Modo de Lectura Continuo:

NOTA: La Alarma Audiovisual viene Configurada de Fábrica en “Alarma Desactivada”

| ARTÍCULO N° | DESCRIPCIÓN | DIMENSIONES | PESO | ||

|---|---|---|---|---|---|

| SIST. INGLÉS (pulg.) | SIST. MÉTRICO (mm) | SIST. INGLÉS | SIST. MÉTRICO | ||

| P-OX KIT | Monitor de Oxígeno PRO OX-100 y Kit de Accesorios | 11 x 9 x 4 | 279 x 227 x 102 | 4.00 lb | 182 g |

| P-OX KIT Euro | Monitor de Oxígeno PRO OX-100 y Kit de Accesorios con Cargador Europeo | 11 x 9 x 4 | 279 x 227 x 102 | 4.00 lb | 182 g |

| P-OX Sensor | Sensor de Oxígeno PRO OX-100 | 1 x 1 | 21 x 20 | 0.03 lb | 16 g |

| P-OX Batt | Batería NiMH 9 V PRO OX-100 | 2 x 1 x 1 | 48 x 26 x 17 | 0.12 lb | 54 g |

| P-OX Charger/US | Cargador de Batería NiMH 12 V PRO OX-100 con Enchufe Tipo EE.UU. | 3 x 2 x 1 | 8 x 60 x 25 | 0.10 lb | 59 g |

| P-OX Charger/EU | Cargador de Batería NiMH 12 V PRO OX-100 con Enchufe Tipo Europeo | 3 x 2 x 1 | 8 x 60 x 25 | 0.10 lb | 59 g |

| P-OX USB | Cable USB PRO OX-100 (72 o 1.8 m) « | 4 x 4 x 1 | 102 x 102 x 25 | 0.11 lb | 50 g |

High-frequency may be an issue with monitors receiving readings around specific welding machines. To test for this, place a piece of metal foil/sheet metal between the monitor and the machine, to protect it from interfering with the circuit board. If the monitor reading is normal, high-frequency equipment is interfering.

Any new 9V rechargeable battery can be substituted in the PRO-OX 100. The specification for the 9V battery is NiMH 280mAh. Additionally, any ordinary (non-chargeable) battery may be used as well.

The PRO OX-100 logs data that can be transferred to a computer via USB cable. Conversion software enables easy capture and export of 50 data points to Microsoft® Excel and Plain text format. Data is recorded in 15 second intervals in CONTINUOUS mode or as needed in SPOT mode.

In order to obtain the data logging software required for the Pro OX®-100, go to aquasolwelding.com, click on the products drop down menu and select “PRO OX-100”. Then click on the provided link, Download «Software and Driver» zip file, complete the form including unit serial number and other required information. Within 24 hours you will receive an email with software attachments for 32 and 64 bit machines.

Calibration can be performed on a weekly basis. There are no other specific recommendations regarding maintenance besides general care of the unit such as cleaning, proper storage, etc.

If a unit is used very frequently (daily) it should be calibrated once a week. If it is not used frequently, it should be calibrated once every three weeks.

Every oxygen monitor is shipped with a Calibration Certificate, Certification of Conformance, and a Test Certificate. The PRO OX-100 does not require a new certificate for every calibration. With the Auto Calibration feature on these units, calibration can be done by the user. There is no need for any unit to be calibrated by Aquasol or a third party.

The Pro OX-100 is battery operated, but can also be operated through a standalone power supply. For specifications on use, refer to section 2.1.1 of the manual. With a full-charge, the battery can supply continuous power for up to two (2) hours.

When using The Pro OX-100 Oxygen Monitor for LESS than two (2) continuous hours, ensure a fully charged battery is installed into the battery housing. Then turn the power switch to the ON position. Continue to use the monitor until operation is complete or the battery indicator displays the «low battery indicator”.

When using the The Pro OX®-100 Oxygen Monitor for MORE than two (2) continuous hours be sure to turn the power switch to the OFF position. If battery is installed, remove from the housing. Then connect the standalone power supply/charger cable to the port. After this step, connect the power supply/charger plug into the nearest working outlet (110V for US type/220V for EU type). Then simply turn the power switch to the ON position. The Pro OX-100 is capable of operating indefinitely with a standalone power supply.

CAUTION: ALWAYS REMOVE THE BATTERY IF USING THE MONITOR FOR MORE THAN 2 CONTINOUS HOURS. FAILURE TO DO SO CAN OVERHEAT THE BATTERY AND SERIOUSLY DAMAGE THE PRODUCT AS WELL AS VOID THE WARRANTY.

The PRO OX-100 can operate in temperatures as low as 0°C (32°F) and as high as 50°C (122°F).

The sensor has a lifespan of approximately one year under normal operating conditions (see manual for operating temperature, proper storage guidelines, etc.).

Sensors are available for purchase. Each sensor has a one year warranty. It is not recommend to keep stock of extra sensors. Sensors are readily available to ship and are lightweight.

If there is an issue starting the pump when pressing the SPOT or CONT button, the pump may be damaged. Contact customer service for an RGA authorization.

If there is no display when the toggle switch is in the ON position, either the battery is drained or the LCD is damaged.

If the battery is drained, simply recharge the battery or use the standalone power supply. Refer to section 1.2.2B of the PRO OX-100 manual for instructions.

If the screen does not light up, replace the battery.

If the LCD is damaged, the unit must be sent to Aquasol Corporation for repair. Contact customer service for an RGA authorization.

If strange symbols appear on the screen when the toggle switch is in the ON position, the display is damaged.

The unit must be repaired. Contact customer service for an RGA authorization.

The keypad is damaged if the keys do not correspond with what is on the display. The unit must be sent to Aquasol Corporation for repair. Contact customer service for an RGA authorization.

To test the PRO OX-100 audiovisual alarm, follow the guidelines below:

If user is unable to set the alarm, the program could be corrupted. Contact customer service for an RGA authorization.

If the alarm does not sound or flash, the alarm is either disabled or damaged. In order to fix this, refer to the manual Section 2.1.3. and follow the instructions. If the issue still persists, the unit must be sent to Aquasol Corporation for repair. Contact customer service for an RGA authorization.

If the alarm light does not blink, even though the sound goes off, the light indicator is damaged. To fix this, the unit must be sent to Aquasol Corporation for repair. Contact customer service for an RGA authorization.

Ensure the sensor is plugged into the sockets properly. After running for 30 seconds, if calibration is successful, the screen will display “CALIBRATION DONE”.

© 2024 Aquasol Corporation. All Right Reserved.